Fred Buckley from the Woodcraft Guild gave us a wonderful demonstration of finishing for our boxes, and a lot of other useful information too!

|

|

|

Many may remember Fred when he spoke to us at our first box making meeting in March. Check out some more of Fred’s lovely work on his Woodcraft Guild profile page.

Preparation

As Fred emphasised, over 90% of the work in finishing is the preparation of the wood before applying any varnish or oil.

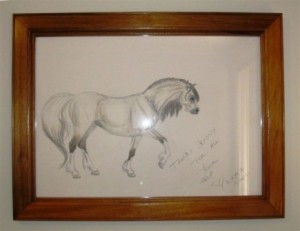

To this end, he showed his lovely James Krenov inspired polishing plane, including how to adjust the blade.

For those interested in building their own polishing plane, David Finck (who was taught by Krenov) has a book and video on the subject. See the trailer for the video.

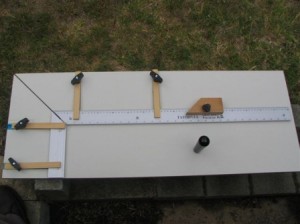

For sanding, Fred uses the Festool ½ sheet orbital sander starting with 120 grit to take out all marks (unless using the polishing plane). He then follows with 180, 220, 240, 400 using a good quality cork sanding block (with the grain!), and a final 1,500 grit after dampening the wood to raise the nap.

For boxes, Fred recommended sanding to 220 grit before cutting dovetails or finger joints to ensure a proper fit before final assembly.

Fred then showed us his two favourite finishes:

Finish 1 – Wipe On, Wipe Off

For the outside of the box, Fred uses a 50/50 blend of Feast Watson Fine Buffing Oil and Clear Varnish applied with a linen cloth. A second coat is applied after drying overnight.

|

|

For a bit more background on this technique, have a look at Bob Flexner’s articles;

Finish 2 – Shellac and Wax

For the inside of the box, Fred recommends shellac and wax for a more inert surface and pleasant odour. The wood is best coated before assembly, taking care when gluing to ensure there is no bleeding onto the prepared surface.

Fred uses a de-waxed blond or super blond shellac dissolved in methylated spirits for 24 hrs at about a 1:8 ratio, and then further diluted by half before use. The shellac is applied with a mop made from clean linen wrapped around cotton wool. At least 7 coats are needed, although each coat can be applied reasonably quickly after the previous since drying takes only a few minutes. Fred uses the Brooklyn Tool and Craft shellac supplied by Woodcraft.

A 1,500 grit wet and dry can then be used with soapy water to prepare for the wax layer.

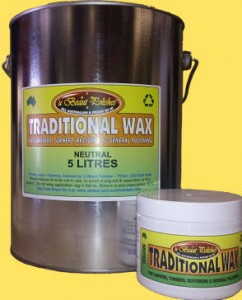

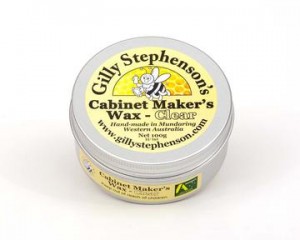

Fred then uses Liberon #0000 very fine steel wool to apply the final wax layer, using U-Beaut Traditional Wax, or Gilly Stephenson’s Cabinet Maker’s Wax for a harder finish, and finishing up by buffing with a clean soft cloth.

|

|

|

So – off to work on those boxes!